Building an Eco-Friendly Factory: How We Built Our 1800 Square Meter Factory

As a company that produces carports and pergolas for our customers, we wanted to expand our production facilities in a way that was environmentally friendly and sustainable. After much research and planning, we decided to build our new factory entirely from wood, using a prefabricated system.

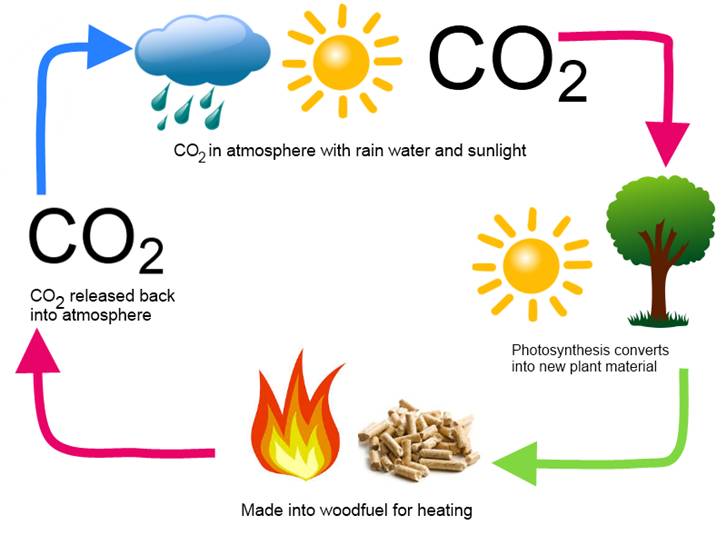

The factory would have a total area of 1800 square meters, an internal height of 5 meters, and 2 front gates for easy access for trucks and deliveries. We chose wood as our building material because we care about CO2 emissions and wanted to be eco-friendly.

One of the biggest challenges we faced was ensuring the strength and stability of the building. To achieve this, we ordered specially designed roof trusses that had to be transported by special means. These trusses would be a key component in the construction of the factory, providing the necessary support for the roof.

We used a prefabricated system for the construction of the factory, which allowed for faster and more efficient construction. This system involved the use of pre-made panels that were assembled on-site. This not only saved time but also reduced the amount of waste produced during construction.

One of the advantages of using wood as a building material is that it is a renewable resource. By building our factory from wood, we were able to reduce our environmental impact and promote sustainability. We also give out fireplace wood to those in need, further reducing waste and promoting social responsibility.

In addition to being eco-friendly, our new factory is also aesthetically pleasing, with a warm and inviting feel. It has allowed us to increase our production capacity while also reducing our carbon footprint. We are proud to have built a factory that not only meets our production needs but also aligns with our values and commitment to the environment.

In conclusion, building an eco-friendly factory entirely from wood was a challenging but rewarding experience. By using a prefabricated system and specially designed roof trusses, we were able to construct a sustainable and efficient production facility. We hope that our efforts will inspire other companies to consider eco-friendly building materials and methods in their construction projects.